What is UV Direct Printing?

UV Printing is a digital printing process that uses ultra-violet light to cure the ink as it is printed. This process is incredibly versatile and is suitable for a wide variety of applications including fine art reproduction, signage, graphics displays, and much more.

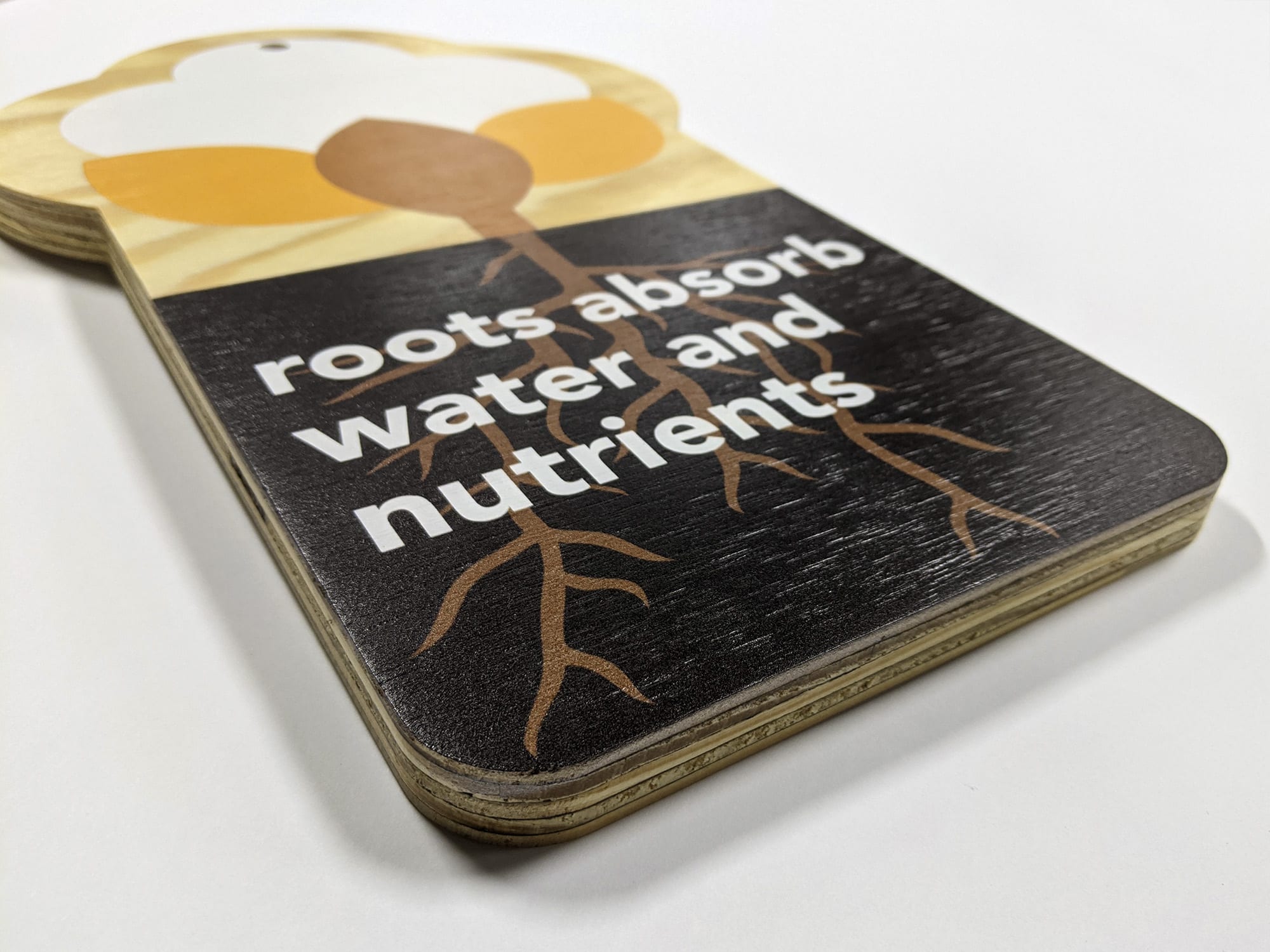

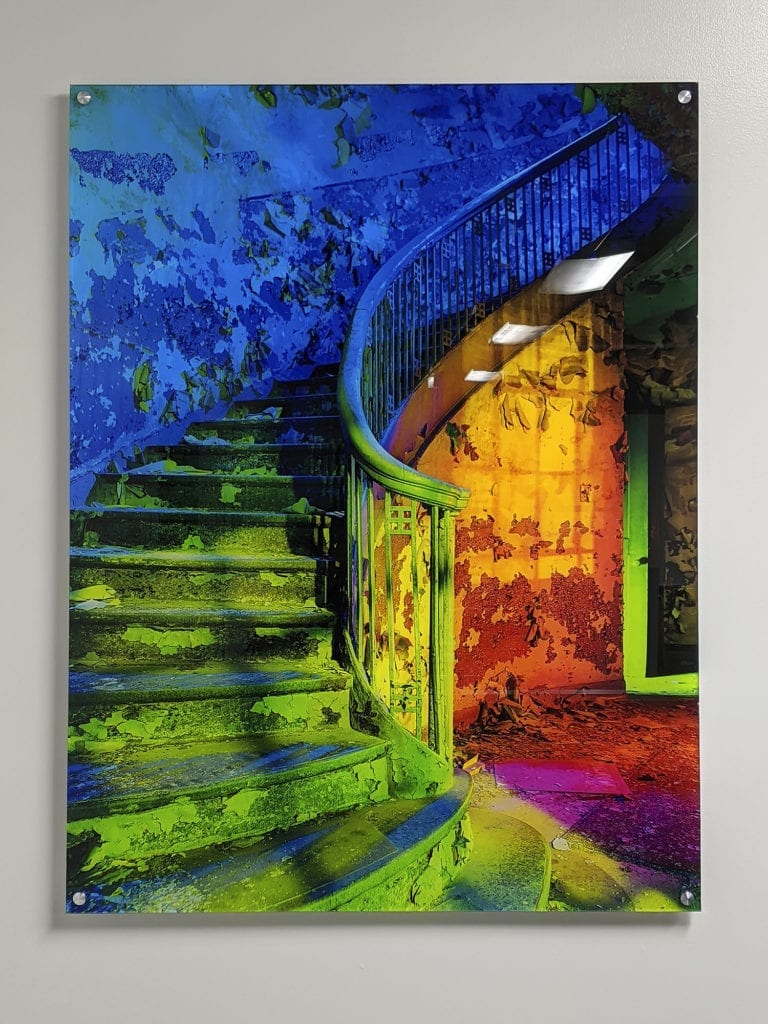

As the printer distributes the ink onto the substrate, specially designed UV lights follow behind and cure the ink almost instantly. Because of this rapid curing process individual dots of wet ink do not get a chance to spread or soak into the substrate. This results in detailed and vibrant prints. UV curing also allows us to print directly onto nontraditional materials like acrylic, glass, and wood – virtually any substrate up to 2″ thick. In addition, UV cured inks are weather-resistant and resistant to fading.

Benefits of UV Direct Printing:

- Prints direct to virtually any substrate, including Wood, Glass, Acrylic, Metal, Plastic, Diebond, Foam core, Sintra, Gatorboard, and more!

- Print on substrates up to 2” in thickness

- 2-sided printing available on many substrates

- 2.5D “Texture Maker” semi-stereoscopic printing – add texture and dimension to prints by layering UV inks to create embossed letters, paint textures, and layer design elements

- Inks cure almost instantly, minimizing absorption and improving color saturation

- Ink cures to a durable, scratch-resistant finish

- UV inks are low VOC and contain no solvents for a lower environmental impact

Check out some creatives applications of our UV Direct Printing below: